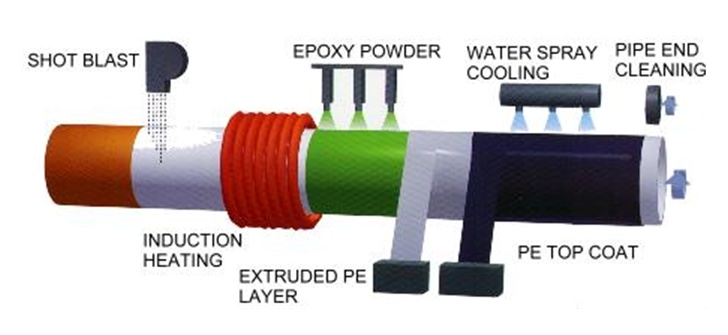

3LPE STEEL PIPES:

First layer is high performance fusion bonded epoxy (FBE>100um),

Mild layer is copolymer adhesive(AD:170~250um) ,

Outer layer is polyethylene coating(PE:1.8~3.7mm).

FBE provides excellent adhesion to pipebody, providing superior long-term corrosion resistance and protection of pipelines.

Copolymer adhesive provides good bonding to the FBE and polyethlene layers.

PE coating provides physical protection to the pipeline.

3LPE pipes are generally used as underground buried pipeline for water, oil and gas.

DIN30670

AS4321

IS3581

GB/T23257

3LPE STEEL PIPES:

First layer is high performance fusion bonded epoxy (FBE>100um),

Mild layer is copolymer adhesive(AD:170~250um) ,

Outer layer is polyethylene coating(PE:1.8~3.7mm).

FBE provides excellent adhesion to pipebody, providing superior long-term corrosion resistance and protection of pipelines.

Copolymer adhesive provides good bonding to the FBE and polyethlene layers.

PE coating provides physical protection to the pipeline.

3LPE pipes are generally used as underground buried pipeline for water, oil and gas.

Standards:

DIN30670

AS4321

IS3581

GB/T23257

Lining: IPN8710 or epoxy coating.

Copyright © Hebei Senhai Pipeline Co., Ltd. All Rights Reserved | Sitemap | Powered by